Ever flicked a light switch and nothing happened? Or maybe your favorite gadget suddenly started acting up? It could be a simple fix – dirty electrical contacts! Don't throw it away just yet; there's a good chance you can revive it with a little cleaning.

We rely on electricity for so much in our daily lives, from powering our homes to keeping our devices running. When electrical connections falter, it can lead to frustration, inconvenience, and even costly repairs or replacements. Intermittent performance, device malfunctions, and decreased energy efficiency are just some of the headaches that dirty or corroded contacts can cause.

This guide will walk you through the simple steps of cleaning electrical contacts at home, helping you restore connections, improve performance, and potentially save money. We'll cover everything from identifying the right tools and cleaning solutions to safe and effective cleaning techniques.

Cleaning electrical contacts is a straightforward process that can significantly improve the performance and lifespan of your devices and appliances. By understanding the importance of clean contacts, gathering the necessary supplies, and following our step-by-step guide, you can tackle this task with confidence. Remember to always prioritize safety by disconnecting power and taking appropriate precautions. Let's dive in and learn how to restore those connections!

Understanding Electrical Contacts

Electrical contacts are the unsung heroes of our electronic world, the crucial interfaces that allow current to flow and devices to function. My own experience with a vintage record player taught me this lesson firsthand. The sound was scratchy and uneven, and I was ready to give up on it. Before tossing it, a friend suggested cleaning the contacts. To my surprise, a bit of contact cleaner and a cotton swab worked wonders, bringing the player back to life! That's when I realized how vital these small connections truly are.

Essentially, an electrical contact is any point where two conductive surfaces meet to allow electrical current to pass. These contacts are found everywhere – in light switches, battery terminals, circuit boards, connectors, and countless other devices. Over time, these surfaces can become contaminated with dust, dirt, corrosion, or oxidation. This build-up creates resistance, hindering the flow of electricity and leading to malfunctions. Think of it like trying to run through mud – it slows you down and makes everything harder.

Different metals react differently. Copper, for instance, is prone to oxidation, forming a green or black coating. Other metals might corrode due to humidity or exposure to chemicals. The type of contact material also influences the best cleaning method. Gold-plated contacts, for example, are more delicate and require gentler cleaning solutions. Recognizing the different types of contacts and potential contaminants is the first step to effective cleaning.

Gathering the Right Supplies

Before you begin, you'll need to assemble a few essential tools and cleaning solutions. The right supplies will not only make the job easier but also ensure you don't damage the electrical components. Think of it like cooking; having the right ingredients and utensils is crucial for a successful dish. Skimping on supplies can lead to frustration and poor results.

Here's a list of items you'll likely need: Isopropyl alcohol (90% or higher is best), Contact cleaner (specifically designed for electronics), Cotton swabs, Soft cloths or microfiber towels, Small brushes (like toothbrushes or paintbrushes), A can of compressed air, Safety glasses, Gloves (nitrile or latex), Screwdrivers (various sizes), Pliers (needle-nose are helpful), Multimeter (optional, for testing conductivity)

Isopropyl alcohol is a fantastic general-purpose cleaner that evaporates quickly and leaves no residue. Contact cleaner is formulated to dissolve stubborn contaminants and corrosion. The soft cloths and swabs are for gentle cleaning, while brushes help dislodge debris in hard-to-reach areas. Compressed air is excellent for blowing away loose particles. Always wear safety glasses and gloves to protect your eyes and skin from chemicals and potential irritants. The screwdrivers and pliers are for disassembling devices to access the contacts, and a multimeter can help you test the connection after cleaning.

A History of Electrical Contact Cleaning

The need to clean electrical contacts has existed since the dawn of the electrical age. Early electrical devices were often crude and prone to corrosion, making regular maintenance essential. Imagine the telegraph operators of the 19th century, constantly cleaning the contacts on their equipment to keep the lines of communication open! This early practice highlights the enduring importance of this simple task.

One persistent myth is that you can use vinegar as a contact cleaner. While vinegar can dissolve some types of corrosion, it's also acidic and can damage certain metals. Plus, it leaves behind a residue that can attract moisture and promote further corrosion. Stick to isopropyl alcohol or a dedicated contact cleaner for safer and more effective results.

As electronics evolved, so did cleaning methods. Early techniques involved harsh chemicals and abrasive materials, often causing more harm than good. Today, we have specialized cleaners and gentle tools that minimize the risk of damage. The key is understanding the specific needs of different types of electrical contacts and choosing the appropriate cleaning method. From simple household appliances to complex industrial equipment, the principle remains the same: clean contacts ensure reliable performance.

Hidden Secrets of Contact Cleaning

One of the best-kept secrets of contact cleaning is that prevention is just as important as the cleaning itself. Regularly inspecting and cleaning contacts can prevent corrosion from taking hold in the first place. A little preventative maintenance can save you a lot of time and trouble down the road. Think of it like brushing your teeth; a little effort every day prevents major dental problems later on.

Did you know that even the oils from your fingers can degrade electrical contacts? Always handle sensitive connectors with gloves or clean hands to avoid transferring contaminants. Also, consider using dielectric grease on certain types of connections to prevent moisture and corrosion. This grease doesn't conduct electricity but seals the contact, protecting it from environmental factors.

Another trick is to use a pencil eraser to gently clean corroded battery terminals. The eraser acts as a mild abrasive, removing the corrosion without damaging the metal. Just be sure to blow away any eraser debris afterward. Ultimately, the secret to successful contact cleaning is a combination of knowledge, proper technique, and a little bit of patience.

Recommendations for Contact Cleaning

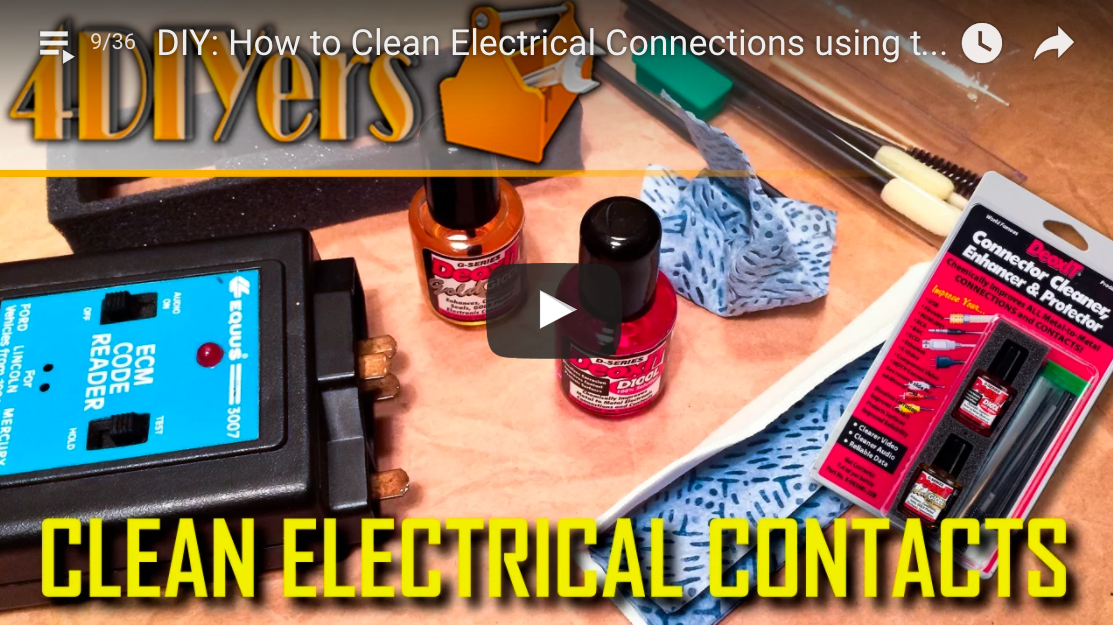

When it comes to choosing contact cleaners, I highly recommend sticking with reputable brands that are specifically designed for electronics. CRC, Deox IT, and MG Chemicals are all well-regarded in the industry. Avoid using generic household cleaners, as they may contain ingredients that can damage electrical components.

For delicate connectors, consider using a lint-free swab or a specialized cleaning brush. These tools will minimize the risk of scratching or damaging the contact surfaces. And remember, a little bit of cleaner goes a long way. Avoid oversaturating the area, as excess liquid can seep into sensitive components and cause short circuits.

If you're working on a particularly stubborn case of corrosion, you might try using a small amount of baking soda mixed with water to form a paste. Apply the paste to the corroded area, let it sit for a few minutes, and then gently scrub with a brush. Be sure to rinse thoroughly with water and dry completely before reassembling the device. This method can be effective for removing heavy corrosion, but always use it with caution.

Safety Precautions When Cleaning Electrical Contacts

Before you even think about touching an electrical contact, safety needs to be your number one priority. Always disconnect the power source before you begin any cleaning procedure. This might seem obvious, but it's a step that's easily overlooked, and it could save you from a nasty shock or even more serious injury. Remove batteries, unplug devices, and turn off circuit breakers as appropriate. It's better to be safe than sorry.

Another critical safety measure is to work in a well-ventilated area. Many contact cleaners and solvents release fumes that can be harmful if inhaled. Open a window or turn on a fan to ensure adequate ventilation. Also, wear safety glasses to protect your eyes from splashes or debris. And as mentioned earlier, gloves are essential for protecting your skin from chemicals and irritants.

Finally, be mindful of static electricity. Static discharge can damage sensitive electronic components. Ground yourself by touching a metal object before handling any circuit boards or connectors. Consider using an anti-static wrist strap for added protection. By following these safety precautions, you can minimize the risks associated with contact cleaning and ensure a safe and successful outcome. Remember, electricity is powerful, so treat it with respect.

Tips for Effective Contact Cleaning

Cleaning electrical contacts isn't just about spraying some cleaner and wiping it off. There's a technique to it that can make a big difference in the results. Start by thoroughly inspecting the contacts to identify the type of contamination and the condition of the metal surfaces. This will help you choose the right cleaning method and avoid damaging delicate components.

When applying contact cleaner, use short, controlled bursts rather than saturating the area. Let the cleaner dwell for a few seconds to allow it to dissolve the contaminants. Then, use a clean swab or brush to gently scrub the contacts, paying attention to any areas with heavy corrosion. Avoid using excessive force, as this can scratch or damage the metal surfaces. After cleaning, use compressed air to blow away any loose debris or residue.

If you're working with connectors, consider using a contact cleaning brush specifically designed for this purpose. These brushes have fine bristles that can reach into tight spaces and remove contaminants without damaging the pins. And always remember to reassemble the device carefully, ensuring that all connections are properly seated. A loose connection can negate all your cleaning efforts.

Troubleshooting Common Contact Cleaning Problems

Even with the best intentions and techniques, you might encounter some common problems during contact cleaning. One frequent issue is stubborn corrosion that refuses to budge. In these cases, you might need to use a more aggressive cleaning solution or a mild abrasive. However, be extremely cautious when using abrasives, as they can easily damage delicate surfaces. Start with the gentlest option and gradually increase the intensity as needed.

Another problem is cleaner seeping into sensitive components. This can cause short circuits or other malfunctions. To prevent this, use a minimal amount of cleaner and avoid spraying directly into openings. If cleaner does seep into a component, use compressed air to blow it out immediately. And always allow the device to dry completely before reassembling it.

Sometimes, even after cleaning, the contacts still don't make a good connection. This could be due to underlying damage to the metal surfaces or a loose connection. Inspect the contacts carefully for any signs of damage, such as cracks or bends. If you find any damage, you might need to replace the connector or component. And always double-check that all connections are properly seated and secured.

Fun Facts About Electrical Contacts

Did you know that some electrical contacts are coated with gold? Gold is an excellent conductor of electricity and is highly resistant to corrosion, making it ideal for use in sensitive electronic devices. However, gold is also expensive, so it's typically used only in applications where reliability is paramount.

Another interesting fact is that the pressure between electrical contacts can affect their performance. Too little pressure can result in a weak connection, while too much pressure can damage the contacts. That's why many connectors are designed with a specific spring force to ensure optimal contact pressure.

And here's a fun one: the term "short circuit" comes from the fact that the electricity is taking a shorter path than intended, bypassing the intended load. This can happen when a wire accidentally touches a grounded surface or when a component fails. Short circuits can be dangerous and can cause fires if not addressed quickly.

How to Clean Specific Types of Electrical Contacts

The approach to cleaning electrical contacts can vary depending on the type of contact you're dealing with. For battery terminals, a simple mixture of baking soda and water can often do the trick. Apply the paste to the corroded terminals, let it sit for a few minutes, and then scrub with a brush. Be sure to rinse thoroughly with water and dry completely before inserting the batteries.

For circuit boards, use a lint-free swab or a specialized cleaning brush and isopropyl alcohol. Gently scrub the contacts, paying attention to any areas with visible corrosion. Avoid using excessive force, as this can damage the delicate components on the board. And always allow the board to dry completely before powering it up.

For connectors, use a contact cleaning brush or a small amount of contact cleaner on a swab. Insert the brush or swab into the connector and gently twist to remove any contaminants. Be sure to blow away any loose debris with compressed air. And always inspect the connector carefully to ensure that all pins are straight and undamaged.

What If Contact Cleaning Doesn't Work?

Sometimes, despite your best efforts, contact cleaning simply doesn't solve the problem. In these cases, it's important to consider other possible causes. It could be that the contacts are damaged beyond repair and need to be replaced. Or it could be that there's an underlying problem with the device itself, such as a faulty component or a broken wire.

If you suspect that the contacts are damaged, inspect them carefully for any signs of wear, corrosion, or bending. If you find any damage, you might need to replace the connector or component. If you suspect that there's an underlying problem with the device, it's best to consult a qualified technician. They can diagnose the problem and recommend the appropriate repairs.

And remember, sometimes the best solution is to simply replace the device. If the device is old or inexpensive, it might not be worth the time and effort to repair it. In these cases, it's often more cost-effective to simply buy a new one.

Listicle: 5 Reasons to Clean Your Electrical Contacts

1.Improved Performance: Clean electrical contacts ensure a smooth and efficient flow of electricity, resulting in improved device performance. Think faster processing speeds, brighter lights, and clearer audio.

2.Extended Lifespan: Corrosion and contamination can shorten the lifespan of your devices. Regular cleaning helps prevent damage and extends their useful life.

3.Cost Savings: By cleaning your electrical contacts, you can avoid costly repairs or replacements. A little preventative maintenance can save you a lot of money in the long run.

4.Enhanced Safety: Dirty or corroded contacts can create heat and increase the risk of fire. Cleaning them helps prevent electrical hazards and keeps your home safe.

5.Environmental Benefits: Extending the lifespan of your devices reduces waste and conserves resources. Cleaning your electrical contacts is a small step you can take to help the environment.

Question and Answer

Q: How often should I clean my electrical contacts?

A: The frequency of cleaning depends on the environment and the type of device. Devices exposed to dust, humidity, or chemicals may need more frequent cleaning. As a general rule, inspect and clean your electrical contacts every 6-12 months.

Q: Can I use WD-40 to clean electrical contacts?

A: While WD-40 can displace moisture and loosen some contaminants, it's not specifically designed for cleaning electrical contacts. It can leave a residue that attracts dust and can actually hinder conductivity. It's best to use a dedicated contact cleaner for optimal results.

Q: What if I'm not comfortable cleaning electrical contacts myself?

A: If you're not comfortable working with electricity or disassembling devices, it's best to consult a qualified technician. They can clean your electrical contacts safely and effectively.

Q: What should I do with the used cleaning supplies?

A: Dispose of used cleaning supplies properly. Follow the instructions on the product labels and dispose of any hazardous materials according to local regulations.

Conclusion of Cleaning Electrical Contacts at Home: Simple Steps for Better Connections.

Taking the time to clean electrical contacts is a small investment that can yield significant returns. By following the simple steps outlined in this guide, you can improve the performance and lifespan of your devices, save money on repairs and replacements, and enhance the safety of your home. So, grab your supplies, roll up your sleeves, and get ready to restore those connections!